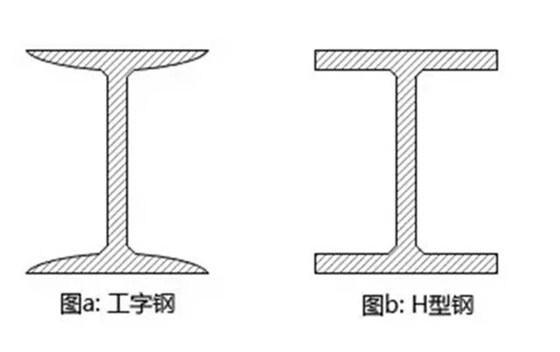

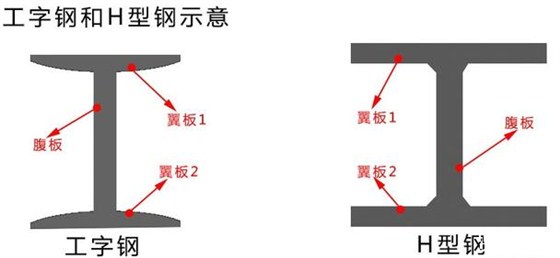

H-section steel and I-beam steel are both connected by a web plate in the middle of the two flanges. The following figure can directly distinguish the two. H-shaped steel is flat and I-beam is inclined.

Of course, the difference between the two is not just the difference on the inside of the flange (also called “leg”). H-shaped steel can be divided into piles, columns, and beams according to the width ratio of the flange web. I-beams are basically commonly used to make beams. , H-shaped steel has the widest application range in steel structure buildings.

Summarize three points

1. With the same amount of steel, H-shaped steel can be made more rigid and stable than I-beam, and its torsion resistance and bending resistance are better than I-beam.

2. In terms of appearance, the upper and lower flange plates of H-shaped steel are much wider than those of I-shaped steel.

3. Technically, H-beams can be hot-rolled or welded, while I-beams are all hot-rolled.

Distinguished by appearance:

Picture a shows an I-beam. As the name suggests, it is an “I”-shaped cross-section steel. The inner surfaces of the upper and lower flanges have an inclination, generally 1:6, and the flanges are thin on the outside and thick on the inside.

Picture b is H-shaped steel. H-shaped steel is a standard “H”-shaped body. The inner surface of the flange has no slope and the upper and lower surfaces are parallel; the inner sides of the two outer edges have no slope and are straight.

From a performance perspective:

1. The I-beam has a small side length and a large height, and can only withstand force in one direction. The H-shaped steel channel is deep and thick, and can withstand forces in both directions.

2. I-beams can only be used for beams, while H-beams can be used for load-bearing columns of structures.

3. The flange of H-shaped steel is wider than that of I-shaped steel, with greater lateral stiffness and stronger bending resistance. Under the same specifications, H-shaped steel has a lighter weight than I-shaped steel.

Compare from a technical perspective:

H-shaped steel has two processes: hot rolling and welding, while I-beam can only be rolled.

HW HM HN H is the general name for H-shaped steel. H-shaped steel is welded; HW HM HN is hot-rolled.

In terms of use:

HW is an H-shaped steel whose height and flange width are basically equal; it is mainly used for steel core columns in reinforced concrete frame structure columns, also called stiff steel columns; it is mainly used for columns in steel structures;

HM is the ratio of H-shaped steel height to flange width, which is roughly 1.33~~1.75. It is mainly used in steel structures: used as steel frame columns and frame beams in frame structures that bear dynamic loads; for example: equipment platforms.

HN is the ratio of H-shaped steel height to flange width greater than or equal to 2; mainly used for beams;

The use of I-beam is equivalent to HN-beam.