Galvanized flat steel bar is a common steel. There are really too many types of steel now. There may be many classifications of steel, and their distinctions are sometimes not very different. Many people are not familiar with the differences and type standards of this steel. There are a lot of doubts, because when we choose building materials, we still need to understand their specific differences and specific situations before we can make a choice.

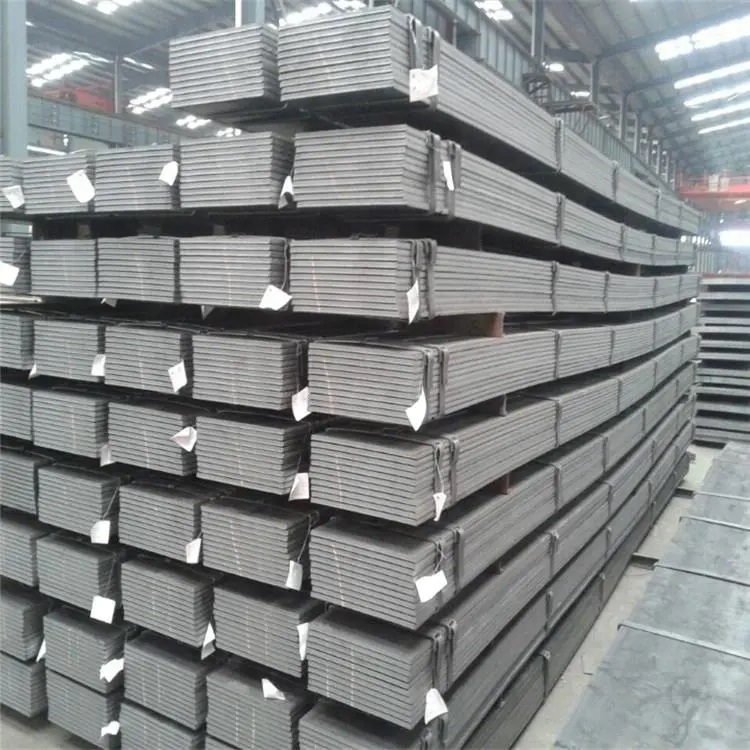

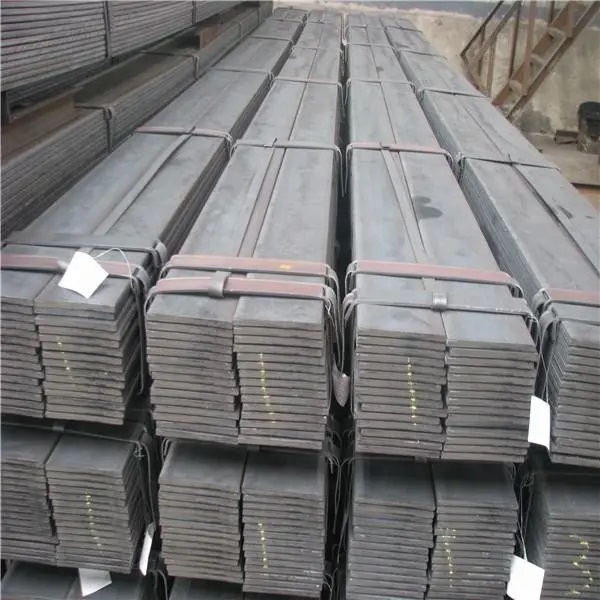

galvanized flat steel

It is called high imitation hot-dip galvanized flat steel, but in fact it does not belong to the scope of hot-dip galvanizing at all. It is just that the flat steel workpiece is processed by the pure white process of cold galvanizing. The cost is extremely low, and the galvanized layer is basically non-existent. , within 0mm~8mm, the processing cost is only 250 yuan per ton at most, and the anti-corrosion performance is extremely poor. Nowadays, the country’s environmental protection control continues to increase, and galvanized flat steel manufacturers are required to increase production costs. This type of product has basically been eliminated from the market!

How to buy galvanized flat steel

Galvanized flat steel manufacturers can select products based on the strength of professional manufacturers. Generally, when choosing, you should choose professional manufacturers. In addition to ensuring product quality, they also do a good job in service work, especially in that they can replace products with poor quality in time and can also assist customers. Reasonable use of galvanized flat steel.

Advantages of galvanized flat steel

1. Product specifications are special. The thickness is 8~50mm, the width is 150-625mm, the length is 5-15m, and the product specifications are closely spaced, which can meet the needs of users. It can be used in place of the middle plate and can be welded directly without cutting. 2. The product surface is smooth and clean. The high-pressure water descaling process is used twice in the process to ensure that the surface of the steel is smooth and clean. 3. Both sides are vertical and the water chestnut corners are clear. The two-pass vertical rolling in the finishing rolling ensures good verticality of both sides, clear corners and good edge surface quality. 4. The size of the product is accurate, with a three-point difference and a difference of the same grade that is better than the steel plate standard; the product is straight and has good shape. Finish rolling adopts continuous rolling process and automatic looper control to ensure that there is no steel stacking or drawing. The product has high dimensional accuracy. The tolerance range, three-point difference, same-line difference, sickle bend and other parameters are better than those of the medium plate, and the plate shape is straight. Good degree. Cold shearing, high precision in length determination.

Traditional hot-dip galvanized flat steel

Galvanized flat steel manufacturers directly immerse the flat steel in zinc and then blow it through air knife blow plating. The thickness of the zinc layer is as high as 25-40um, so it has good corrosion resistance and is the best choice among ordinary engineering materials. However, its disadvantages are that the cost is slightly higher and the appearance is slightly rough!