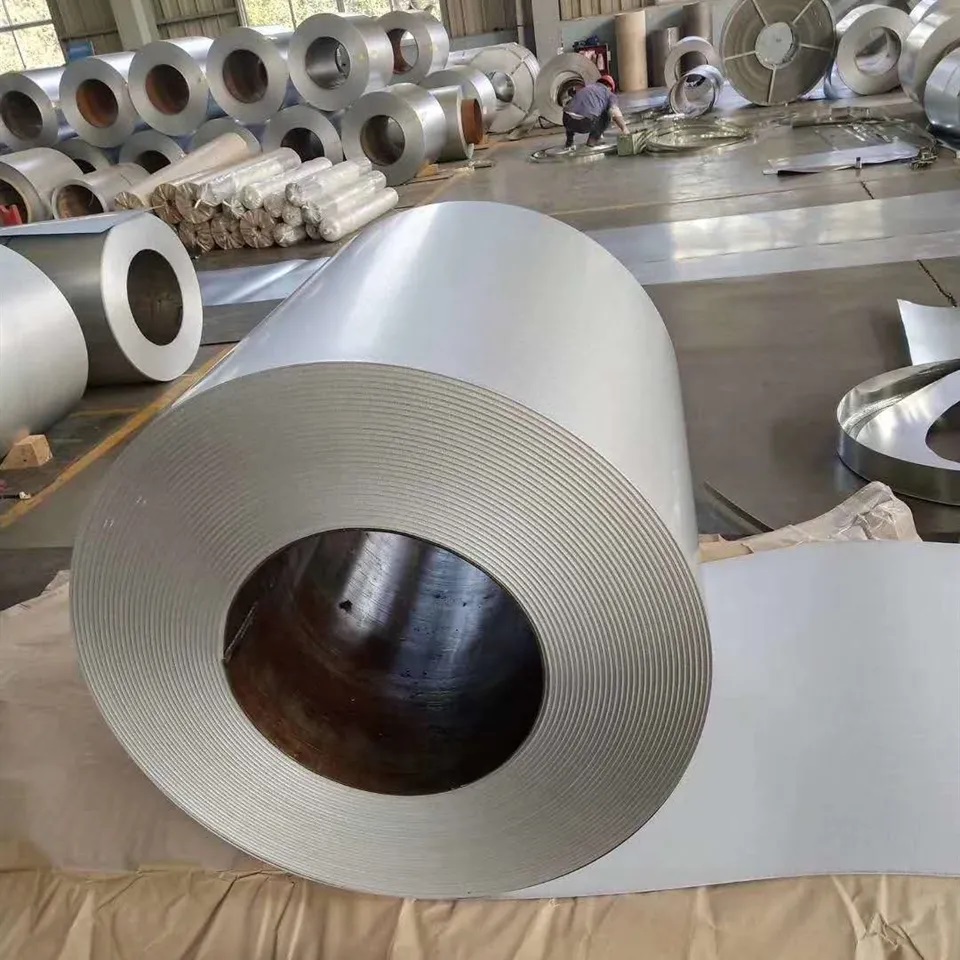

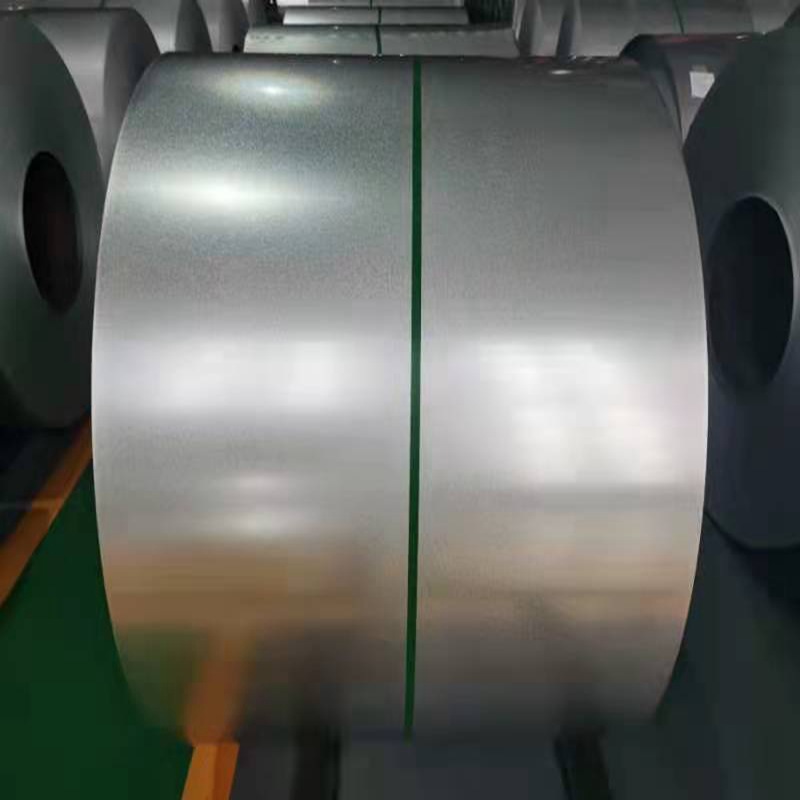

The full name of aluminized plate is “hot-dip aluminized steel plate”, which is similar to hot-dip galvanized steel plate in terms of manufacturing process. But its heat resistance is better than galvanized steel plate. Aluminum plate has the following 5 characteristics:

1. High temperature resistance: Due to the specific combination of the steel plate base material and the coating structure, an iron-aluminum alloy is formed, which makes the aluminum plate have excellent high temperature resistance. At 450℃, extremely high reflectivity can be guaranteed. Above 480°C, the coating will appear gray. At temperatures as high as 650°C, the protective layer that prevents oxidation of the steel plate is still intact and no peeling off is seen.

2. Heat reflectivity: At a high temperature of 480 degrees Celsius, the aluminized plate can reflect 80% of the incident heat. Therefore, aluminized sheets can be made into efficient thermal barriers or heat reflectors in high-temperature applications, rapidly increasing the temperature in the furnace through effective heat reflection.

3. Mechanical strength: At room temperature, the mechanical strength of the aluminum plate is consistent with the mechanical strength of its base material. At the same high temperature of 480°C, the strength of aluminized steel plates is 10 times that of aluminum plates, so the thickness of the steel plates can be reduced by at least 30%.

4. Corrosion resistance: During the hot-dip plating process, the molten aluminum immediately reacts with oxygen in the air to form a protective layer of Al2O3, which immediately passivates the surface of the steel plate. This protective layer is very stable and insoluble in water. Even if the surface of the steel plate is scratched later, this protective layer has a self-healing function. Therefore, aluminized sheets have extremely strong resistance to chemical corrosion.

5. Ecological properties: Aluminized plates that are not chemically passivated have no impact on health and can therefore be used for food processing. Test reports from many professional groups confirm that it is harmless to the human body and is an environmentally friendly product. Aluminized panels are completely recyclable. Aluminized plate is comparable to stainless steel but the price is only one-third of stainless steel

![]()

Aluminized sheets are generally used in:

1. Car and motorcycle mufflers, exhaust pipes, and fuel tanks.

2. Combustion furnaces, heat exchangers, dryers, air conditioners, etc.

3. Household water heaters, gas stoves, bread boxes, chimneys, microwave ovens, food processing machinery, electric ovens, and cooking utensils.

It can also be used for building covers, walls, ceilings and other thermal insulation components.